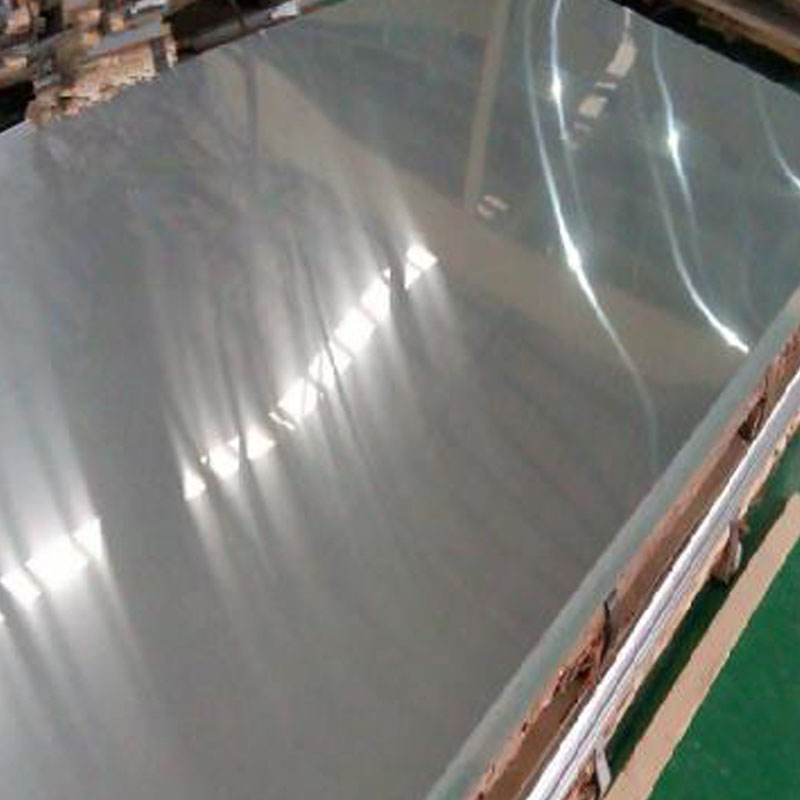

Lembaran Keluli Tahan Karat 2B Permukaan 1Mm SUS420 Plat Keluli Tahan Karat

renda Asal: China

Permohonan: Pembinaan, Industri, Hiasan

Standard:JIS, AiSi, ASTM, GB, DIN, EN

Lebar: 500-2500mm

Gred: 400 Siri

Toleransi:±1%

Perkhidmatan Pemprosesan: Membengkok, Kimpalan, Memotong

Nama produk: Lembaran Keluli Tahan Karat 2B Permukaan 1Mm SUS420 Plat Keluli Tahan Karat

Teknik: Dikumpul Panas/Sejuk

Tempoh Harga: CIF CFR FOB EX-WORK

Pembungkusan: Pakej Standard Layak Laut

Bentuk:Plat Segiempat

MOQ: 1 tan

Masa penghantaran: 3 ~ 5 hari bekerja

Kemasan permukaan:2B/BA/HL/NO.4/8K/Timbul/Emas/Emas Mawar/Emas Hitam

Tepi: Tepi Celah Tepi Kilang

Sampel: Boleh didapati

Jenis: Pinggan

Persijilan:Sgs

Panjang: 3000mm-12000mm

Nombor Model:SUS420

Keupayaan Bekalan:10000 Tan/Tan sehari

Butiran Pembungkusan: palet kayu atau sebagai keperluan pelanggan

Pelabuhan:Shanghai

| produk | Lembaran/pinggan Keluli Tahan Karat |

| gred | 200 siri: 201/202Siri 300: 301/304/304L/305/309S/310S/316/316L/316LN/316Ti/317/317L/347/347H400 siri: 405/409/409L/410/420/430/440C/444/4447 600 siri: 630/631 keluli tahan karat dupleks: 2205/2507/2520 keluli tahan karat super: 904L |

| teknologi | canai sejuk/gulung panas |

| ketebalan | 0.1-150mm |

| lebar | 500-3000mm atau sebagai keperluan anda |

| rawatan permukaan | 2B/garis rambut/8k cermin digilap/NO.1/NO.4/BA |

| ciri | kekerasan dan kekuatan yang tinggi/100% dikitar semula/tahan api/bukti wter/anti kakisan/tahan suhu tinggi/mudah dibersihkan dan diselenggara/seumur hidup panjang/tahan lama |

| jenis pemprosesan | nyahgelung/memotong/mengimpal/mengisar permukaan/membengkok |

| MOQ | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Timbul |

| Istilah harga | CIF CFR FOB EXW |

| Tempoh pembayaran | bawah $10,000, bayar penuh melalui TTmelebihi $15,000. 30% TT deposit terlebih dahulu dan 70% TT baki sebelum penghantaran |

| Permohonan | bidang pembinaan, industri pembinaan kapal, petroleum, industri kimia, industri perang dan elektrik, industri pemprosesan makanan dan perubatan, penukar haba dandang, bidang jentera dan perkakasan |

| Gred | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 . 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |